Services

CEMENTITIOUS FIRPROOFING

Cementitious fireproofing refers is a type of fire protection material applied to structural elements, such as steel and concrete, to enhance their fire resistance. Composed primarily of cement, aggregates, and additives, this material is mixed with water to form a slurry that is sprayed or troweled onto surfaces. Upon drying, it forms a hard, dense layer that insulates the substrate from the effects of fire by providing thermal resistance and preventing the spread of flames. Cementitious fireproofing is commonly used in commercial and industrial buildings. Its effectiveness in withstanding high temperatures and prolonging structural integrity makes it a crucial component of passive fire protection systems.

INTUMESCENT FIREPROOFING

Intumescent fireproofing is a type of passive fire protection that reacts to heat by expanding and forming a protective insulating char layer, which helps to delay the transfer of heat to the underlying substrate. Typically composed of a combination of binders, fillers, and fire-retardant additives, intumescent coatings are applied as thin films to various surfaces, including steel beams and columns. When exposed to fire, the coating undergoes a chemical reaction, causing it to swell and form a thick, heat-resistant foam-like layer that acts as a barrier against fire spread. This expansion mechanism not only insulates the substrate but also helps maintain its structural integrity, thereby providing valuable time for occupants to evacuate and for firefighting efforts to be carried out. Intumescent fireproofing is widely used in commercial buildings, industrial facilities, and infrastructure projects where fire safety regulations are stringent.

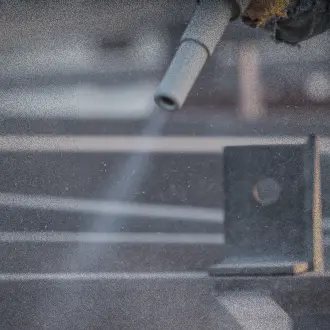

BLASTING STEEL

Sandblasting steel is a surface preparation method used to remove rust, old paint, mill scale, and other contaminants from steel surfaces by propelling fine particles of abrasive material at high velocity. Typically, sandblasting involves the use of compressed air to propel abrasive media, such as sand, garnet, or steel grit, onto the steel surface. This process effectively strips away any surface imperfections, leaving behind a clean, roughened surface that is ideal for coating or painting applications. Sandblasting is widely utilized in industries such as construction and manufacturing, where steel components require thorough cleaning and preparation before further processing or finishing.

STEEL COATINGS

Steel coatings refer to protective layers applied onto steel surfaces to enhance their resistance against corrosion, abrasion, and environmental degradation. These coatings are crucial for extending the lifespan and maintaining the structural integrity of steel components in construction sectors. There are diverse types of steel coatings available, ranging from traditional paint coatings like epoxy, polyurethane, and acrylics, to more specialized coatings such as galvanization, thermal spraying, and powder coatings. Each type of coating offers specific advantages, such as improved adhesion, chemical resistance, UV protection, or decorative finishes, depending on the requirements of the application and the operating environment.

THERMAL INSULATION

Thermal insulation is a material or combination of materials designed to reduce the transfer of heat between surfaces with different temperatures. It is essential for maintaining comfortable indoor temperatures, increasing energy efficiency, and preventing heat loss or gain in buildings, industrial equipment, pipelines, and various other applications. Thermal insulation materials work by minimizing three main modes of heat transfer: conduction, convection, and radiation. Common insulation materials include fiberglass, mineral wool, foam boards, cellulose, spray foam, and reflective barriers. These materials trap air pockets or incorporate insulating gases to hinder the transfer of heat energy. Properly installed thermal insulation can significantly reduce energy consumption for heating and cooling, improve indoor comfort, and contribute to sustainability efforts by lowering greenhouse gas emissions associated with energy use.

ACOUSTIAL INSULATION

Acoustical insulation, also known as soundproofing or sound insulation, is the process of reducing the transmission of sound between spaces or dampening unwanted noise within a specific area. It involves the use of specialized materials and construction techniques designed to absorb, block, or redirect sound waves, thereby improving acoustic comfort and privacy. Acoustical insulation materials typically include dense and porous substances such as fiberglass, mineral wool, foam panels, rubber, or acoustic baffles. These materials are strategically installed in walls, floors, ceilings, and other structural elements to mitigate sound transmission through absorption, reflection, or diffusion. Acoustical insulation is crucial in various environments, including residential buildings, offices, theaters, recording studios, and industrial facilities, where controlling noise levels is essential for creating a comfortable and productive environment. Properly implemented acoustical insulation helps reduce noise pollution, enhance speech intelligibility, and maintain privacy, contributing to overall well-being and quality of life.

FIRSESTOP/SMOKESEAL

Firestop/smokeseal refers to a vital component of passive fire protection systems designed to prevent the spread of fire and smoke through openings in walls, floors, ceilings, and joints in buildings. It involves the installation of fire-resistant materials such as intumescent sealants, fire-rated caulks, foams, and firestop pillows to seal penetrations created by pipes, cables, ducts, and gaps in construction elements. These materials expand or swell when exposed to high temperatures, forming a tight barrier that restricts the passage of flames, hot gases, and smoke. Firestop/smokeseal systems play a critical role in compartmentalizing fire hazards, slowing down their progression, and providing occupants with valuable time to evacuate safely in the event of a fire. They are essential for maintaining the integrity of fire-rated barriers and ensuring compliance with building codes and fire safety regulations. Regular inspection, maintenance, and proper installation of firestop/smokeseal systems are crucial for their effectiveness in enhancing overall fire safety in buildings.

FLOOR COATINGS

Floor coating refers to a protective layer applied to the surface of floors to enhance durability, aesthetics, and resistance to wear, chemicals, and other environmental factors. These coatings can be applied to various types of substrates, including concrete, wood, metal, and tile, depending on the specific requirements of the application. Floor coatings come in a variety of formulations, such as epoxy, polyurethane, acrylic, and epoxy-polyurethane hybrids, each offering unique properties and benefits. Epoxy coatings, for example, are known for their excellent adhesion, chemical resistance, and durability, making them suitable for high-traffic areas like warehouses, garages, and industrial facilities. Polyurethane coatings provide superior abrasion resistance and UV stability, making them ideal for outdoor and commercial settings. Acrylic coatings offer quick drying times, ease of application, and good color retention, suitable for decorative and light-duty applications. Proper surface preparation is essential for ensuring adhesion and longevity of flooring coatings, which play a crucial role in enhancing the appearance, performance, and lifespan of floors while simplifying maintenance and cleaning efforts.

SPORT FLOOR COATINGS

Sport floor coatings are specialized coatings designed to enhance the performance, durability, and safety of floors in sports facilities. These coatings provide a protective layer over the surface of the floor, guarding against wear and tear from heavy foot traffic, equipment, and sporting activities. They typically offer features such as impact resistance, slip resistance, and shock absorption, ensuring a safer environment for athletes. Sport floor coatings come in various types, including polyurethane, epoxy, and acrylic, each with its own set of advantages depending on the specific requirements of the sport and the facility. Additionally, these coatings can be customized to meet specific aesthetic preferences, such as team colors or logos, further enhancing the visual appeal of the sports facility. Overall, sport floor coatings play a crucial role in maintaining the longevity and performance of sports floors while providing a safe and visually appealing environment for athletes and spectators alike.

TRAFFIC TOPPING

Traffic topping coating refers to a specialized type of surface treatment applied to floors in areas with high foot or vehicle traffic, such as parking lots, warehouses, or industrial facilities. These coatings are designed to withstand heavy wear and tear, offering exceptional durability and resistance to abrasion, chemicals, and UV radiation. Traffic topping coatings can come in various formulations, including epoxy, polyurethane, or acrylic, each tailored to meet specific performance requirements. They provide a protective layer that not only extends the lifespan of the underlying substrate but also enhances its appearance and safety by offering features such as slip resistance and easy maintenance. Additionally, traffic topping coatings can be customized with additives like aggregates or color pigments to meet specific aesthetic or functional needs, making them a versatile solution for a wide range of applications where durability and performance are paramount.